Jewellery Creation Process

Crafting of Brilldor jewellery is proceded by meticulous planning and preparation. The inspiration behind our pieces varies, it may be an unusual gemstone, a jewellery competition or a previous, successful design, but they are designed with multidimensional forms and their harmony in mind. We hand sketch the jewellery shape at length, taking functionality, comfort, durability and protection of gemstones and pearls in mind.

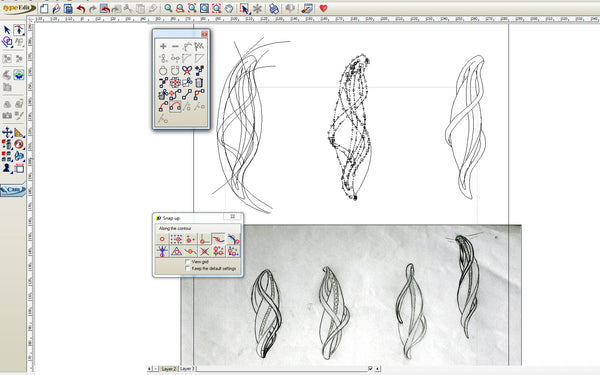

When one of the sketches is chosen to be crafted, we scan the traditional hand drawing to a computer and refine the lines, the rhythm and examine the overall impact. Most jewellery makers start crafting directly from the hand sketches thus relying on rough estimates rather than careful measurements. We believe that this method leads to discrepancy between the original plans and the actual outcome, and often the original spark or appeal that was in the plans is lost. This is why we use design software to refine our plans; we believe that it is this stage that decides how impressive the jewellery items will actually be.

After we have made a two dimensional drawing of clear and fine lines, we move onto thinking about the various sides and angles of the jewellery item. This again is a point when many unexpected anomalies in shape and executability may arise. These play a part in refining the main face of the piece and also allow us to add more intricate detail and subtlety to the small item.

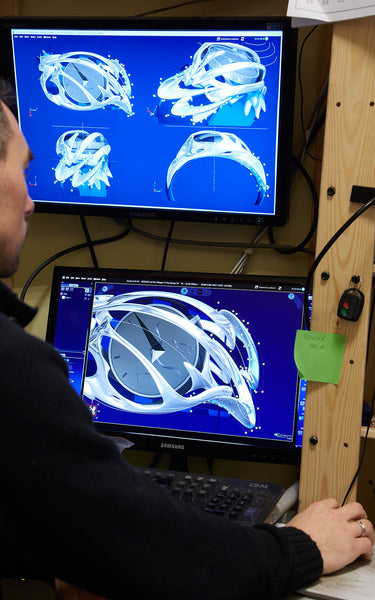

At the next stage of the process, we create three dimensional shapes with the help of the design software which allows us to notice and resolve imperfections. This new technology allows us to examine the jewellery design from all angles so we easily recognise if there is a break in a curve, a crease on a surface or any other problem that needs to be resolved.

When the design process in completed, we need to make decisions about the crafting method based on the shape, material and complexity of the piece. The crafting of the jewellery item is either done completely by hand, or by making a mould of certain details with a high-precision 3D printer and creating the precious gold metal version of the part based on that.

When the design process in completed, we need to make decisions about the crafting method based on the shape, material and complexity of the piece. The crafting of the jewellery item is either done completely by hand, or by making a mould of certain details with a high-precision 3D printer and creating the precious gold metal version of the part based on that.

The refining of the piece by hand and the building together of parts requires a substantial amount of practice as well as special tools and technology. In our case, we also rely on teamwork, as we primarily create one-off unique items and often we find ourselves facing new challenges. So we put our heads together, and everyone shares their best ideas. To create jewellery specialities like ours, we need exceptional goldsmiths who are not only gifted in their manual abilities but also have a strong sense of style and aesthetics, are intelligent, resourceful and open to new challenges every day of the week. So, as our exceptional creations and awards show, teamwork is highly important.

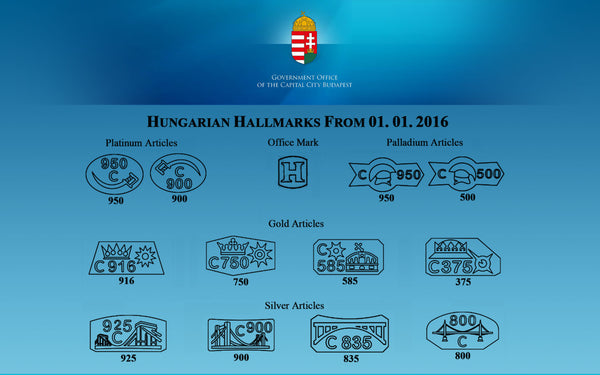

The finished piece is then taken to the Assay's Office where the item receives and internationally certified hallmark stamp that verifies the guaranteed standard of fineness of the metals used, the name and integrity of the maker and the year the piece was made and tested.

Afterwards, the completed precious metal piece has to undergo a number of short processes. It is at this stage that the carefully selected gemstones, diamonds and/or pearls are set, by an outstandingly gifted and knowledgeable colleague who ensures the settings are both protective and attractive. This is done under a microscope with meticulous precision and at an artistic level. It is at this stage when decorative engraving, enamels, decorative and enhancing treatments are also applied to the piece.

The finished object is then photographed, its data archived before we place them in elegant packaging and create a warranty certificate or "passport". We call this document a "passport" because it is our belief that the jewellery specialities that we create are so durable and captivating that they will be cherished heirlooms for generations to come.