Flirt set - 02

In the previous blog post, we described how thoughts and emotions inspired the design of the Flirt collection, consisting of a necklace, matching bracelet, ring and earrings all adorned by akoya and other pearls and brilliant cut diamonds.

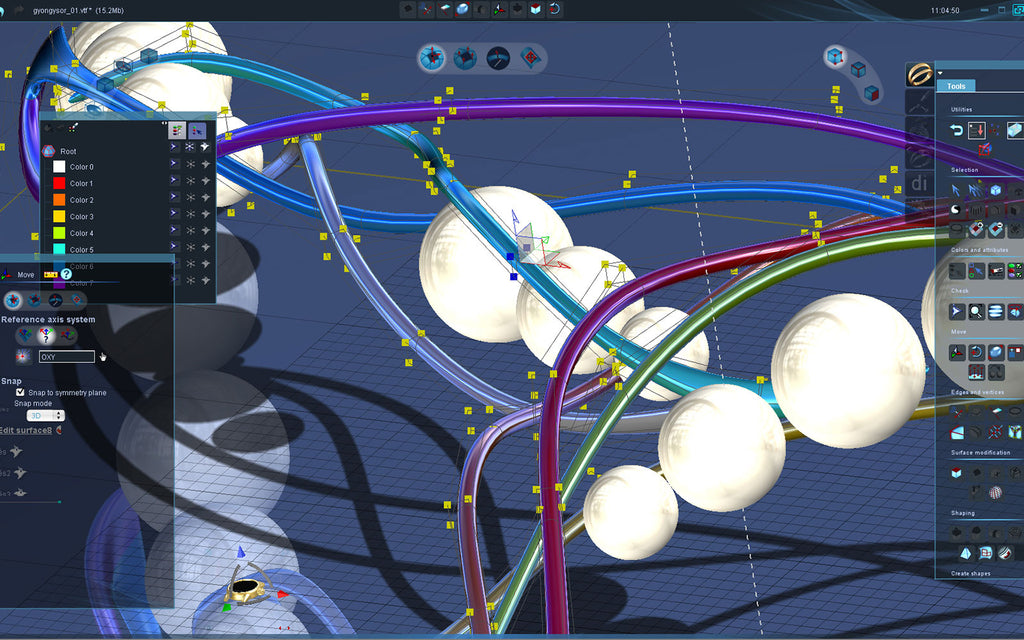

The idea and the hand sketches were followed up by the 3D design phase which was the most lengthy stage of the entire creation process. Excitement accumulates as the form slowly takes shape and we are bursting with energy to make it come alive.

Since we have the 3D design tools and 3D printer, we are able to create more sophisticated designs, to view pieces from every angle and control the design of jewellery with greater precision. It is also easier to determine the width of a design, which determines the amount of gold and other precious metals used to ensure durability, comfort and weight to keep the price low.

3D technology helps to ensure the safety of the stone settings, the operations of the locks, a 10 step process of reworking the surface as well as other technical issues. Of course, a lot of professional know-how is needed in terms of the technical possibilities, understanding the needs of clients and how to avoid frequent errors to ensure that a jewellery collection is not merely beautiful, but also comfortable, secure and perfectly designed. In other words, befitting our motto of creating lasting value for generations to come. By printing the 3D form, a statue that precisely shows the intricate shape of the jewellery that is to be made, the place of the stones and pearls, we obtain an accurate template to craft the jewellery set by hand.

First, the amount of gold to be determined. With precious metals including special white gold alloys which are also very valuable, minimalizing waste is very important. We therefore calculate the expected mass of each component of the jewellery.

We create the intricate parts using ancient goldsmith techniques making sure the measurements are precise and perfect to avoid any errors in the jewellery pieces.

When we finish making a piece, we continue by bending the crude surface and black coloured gold parts. The printed model is very useful at this stage as we can press the golden wires onto the model to create the exact shape. Precision is of utmost importance here. Even a millimetre or a single degree of deviation can upset the refined plan. I think that this is the aspect of our work that is key in being able to provide our clients seeking custom-made unique jewellery with perfect pieces, which is the reason for the high degree of satisfaction among our clients. A lot of jewellery makers are unable to craft exactly the same pieces that they designed, small deviations become intensified in the finished pieces. Let us imagine the building of a tower. If there is a small almost undiscernible unevenness at the base it becomes a spectacular skew by the time it reaches the top. In the architecture of buildings or jewellery precision is a very delicate matter.

When the parts of the necklace were finished, we created the raw, angular metal parts. First we smoothed out the surface with rough rasp, but the result was still quite unattractive. We used finer rasps and sanding paper to work on the gold parts. This is probably the most time consuming stage of the creation process because the thin jewellery parts have a lot of surface which all need to be rubbed thoroughly but without causing deformation in the pieces. Moreover, this stage has to be repeated seven times to allow polishing by a soft cloth and polishing disks.

We are now finished with all the parts of the necklace, bracelet, earrings and ring. Although they are not black anymore, the surface is smooth, but we can still only see a mass of thin wires. How will this all come together a jewellery?

Also in Flirt set

Christmas is coming...

Flirt set - 01

This is how a hand-made, bespoke Brilldor jewelry set made. The full jewellery family contains a bracelet, a ring, a pair of earrings and an exclusive necklace with lots of high quality Japanese akoya pearls and, and top grade brilliant cut diamonds.

We took several images and video about custom made jewelry design and creation. You can see, how we do skeching by hand, designing by computer in 2d, 3d, making beautiful CGI animation. Soon we post detailed information about making process, as long as rough metal parts turn to be a beautiful high-end jewellery set.